CPR Repairs / Coats Ballast Manifold on Laker Ship

CUSTOMER: Ontario based shipping company

APPLICATION DATE: December 2003

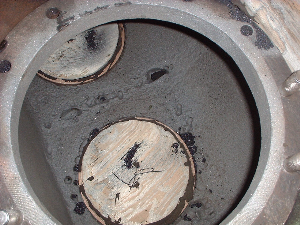

PROBLEM: Ballast manifold had suffered with Cavitation damage over past 25 years

SUBSTRATE: Cast Iron

APPLICATION METHOD: Substrate was blasted to a SSPC-SP10 and our paste grade metal was used to fill in voids followed by two coats of our fluid coating grade materials.

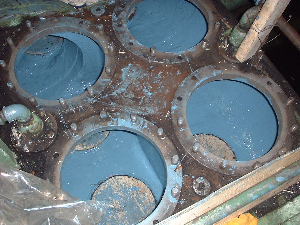

CPR FACTS: Marine Metal is a great filler material and easy to work with. The CPR Material coating was applied to protect the casting from further cavitation damage and give the manifold many more years of life.

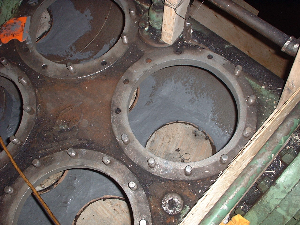

PHOTOGRAPHS

Manifold was blasted to SSPC-SP10, 3-4 mil profile.

Our paste grade metal was applied to fill in pitting and large voids.

Second of two coats of coating grade materials were applied followed by general cleanup.