CPR Coating for Low Pressure Service Water Pump Impeller

CUSTOMER: A nuclear power plant in Ontario

APPLICATION DATE: 2002

PROBLEM: Extensive cavitation on LPSW pump impeller

SUBSTRATE: Steel

APPLICATION METHOD: After surface preparation was applied to restore impeller vanes to original profile. Final topcoat consisted of two coats of CPR Material.

CPR FACTS: Customer chose to repair deepest areas of cavitation via welding. Note: CPR today offers a more highly cavitation resistant coating.

PHOTOGRAPHS

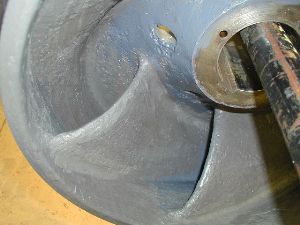

Overall view of impeller after surface preparation.

Close up of impeller vanes showing welding and remaining cavitation pits in blades.

CPR Material applied and smoothed over blades.

Completed application after two coats of CPR Material. Impeller was dynamically balanced prior to return to service.