CPR – Repairs and Coats Chillers in Condo in Scarborough, Ontario

CPR – Restores & Protects

Condominium HVAC Chiller

CUSTOMER: Condominium building in Scarborough, Ontario

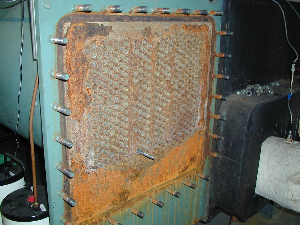

PROBLEM: Severe corrosion of HVAC chiller in condominium

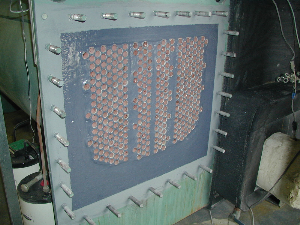

PRODUCTS: Pit filling composite paste grade metals followed by two coats of fluid grade wear resistant polymer / eposy

SUBSTRATE: Carbond Steel Tube Sheet and Copper Tubes.

CPR: Substrate was blast cleaned under negative pressure to contain dust. Filler materials and protective coatings were applied according to manufactures recommendations.

FACTS: Chillers and heat exchangers coated with with these types of materials prevent bimetallic corrosion and enhance the fulid flow as a bonus thus cutting energy costs.

Note: It is cirtially important that both the tube steet and the end covers/water boxes are both coated at the same time. The purpose is of course the elimination of bimetallic corrosion. If there is more than one metal involved in a common fluid environment, the least noble of metals will certainly suffer from with an increased amount of corrosion. By eliminating multiple metals in a fluid enviroment, you will reduce if not eliminate corrosion.

PHOTOGRAPHS