CPR Repairs and Coats Cooling Tower Water Holding Tanks

CPR Repairs and Coats Water Tanks

CUSTOMER: Bank operations building in Toronto

PROBLEM: Corrosion of tank holding cooling tower water – all four compartments.

PRODUCTS: Paste Grade Metal Composite followed by two coats of Epoxy Polymers.

SUBSTRATE: Carbon Steel

APPLICATION Procedure: Substrate was blasted to a 3-4 mil profile and then pit filled with a paste grade epoxy polymer and then over coated with two coats of coating grade epoxy polymers.

CPR Notables: Blasting was done under negative pressure to contain dust. All pit filling and coating materials were 100% solid Epoxy Polymers with no VOC’s that would cause any buiding environment issues.

PHOTOGRAPHS

Corrision shown prior to the commencement of work.

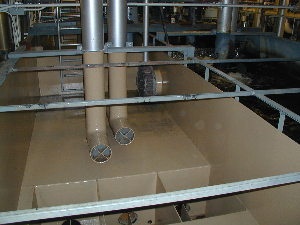

Filling the pits and stripe coating prior to the application of the final two coats of Epoxy / Polymers.

Pin hole checks were performed after the second application has cured.

Back into service timing was completed within the customer requirements with absolutely no VOCs.