CPR Repairs Corrosion on Cooling Water Heat Exchanger

CUSTOMER: Steel mill in Ontario

APPLICATION DATE: July 2001

PROBLEM: Corrosion damage to heat exchanger especially division bar and sealing areas.

SUBSTRATE: Steel & cast iron

APPLICATION METHOD: After proper surface preparation, application techniques for heat exchanger refurbishment were used to restore eroded division bars and seal areas. All wetted surfaces including tubesheets, covers and water boxes were coated with polymer/epoxy materials.

CPR FACTS: Heat exchangers treated with polymer/epoxy materials have been in uninterrupted service for upwards of 20 years.

PHOTOGRAPHS

End cover showing thinning of division bar.

Completed end cover with division bar restored to original profile with paste and coating grade materials.

Water box treated in identical manner to end cover.

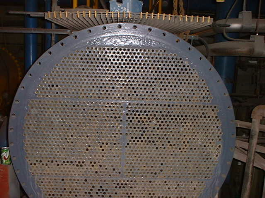

Tubesheet completely protected from future corrosion.