CPR Repairs Corrosion Damage To Multiport Brine Valve

CUSTOMER: A papermill in Ontario

APPLICATION DATE: July 2005

PROBLEM: Corrosion had caused severe deterioration of the substrate on two different multiport valves that operated in the steam plant of this paper mill. The valves were no longer operating as designed due to the bypass of the sealing surfaces. One valve handles a 24 beaume brine solution while the second handles a 30-93% sulphuric acid solution

SUBSTRATE: Steel

APPLICATION METHOD: After thorough surface preparation CPR Material was formed to restore the original tolerances. CPR Material was used as the protective coating in the brine valve and CPR Material as the coating for the sulphurice acid service.

CPR FACTS: This repair was less expensive and time consuming than replacement option. The CPR coated valves would be expected to outlast the original valves.

PHOTOGRAPHS

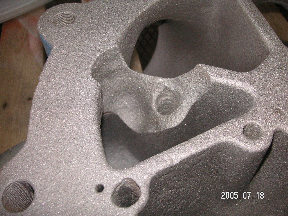

View of brine valve after abrasive blasting showing extensive corrosion pitting and loss of machined sealing surfaces. Completed job. Seal surfaces returned to original profile and black CPR Material applied as coating.

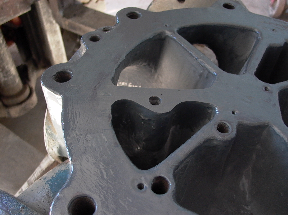

Acid valve showing extensive damage where previous coating had failed

Completed coating and damage perfectly repaired to original contours

Dry run fitting of former mould clearly showing degree of damage to shaft

Mould in place ready for injection of CPR Material

Completed job with mould removed and ready for installation of new bearing