VOITH Liquid Ring Vacuum Pump Repaired and Coated with CPR Material

CUSTOMER: A papermill in Ontario

APPLICATION DATE: March 2003

PROBLEM: Normal operation had caused corrosion damage plus wear & tear on this liquid ring vacuum pump. Pump casing had actually holed through and OEM pump tolerances were gone in critical areas of vacuum pump including rotor and cone gap.

SUBSTRATE: Cast Iron

APPLICATION METHOD: After thorough surface preparation CPR repair composites and protective coatings were applied, formed and machined according to proven CPR application technologies. All OEM tolerances were restored.

CPR FACTS: This repair was less expensive and time consuming than replacement or exchange option

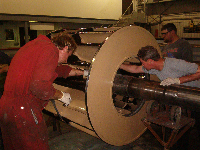

PHOTOGRAPHS

Before & after view of end cover and cone

Pump body perforations repaired with CPR and doubler plate

Pump rotor shrouds restored and rotor coated

Pump body internals with washout repaired and body coated

Additional view of end cover and pump reassembled and ready for return to customer